PRICE ON REQUEST

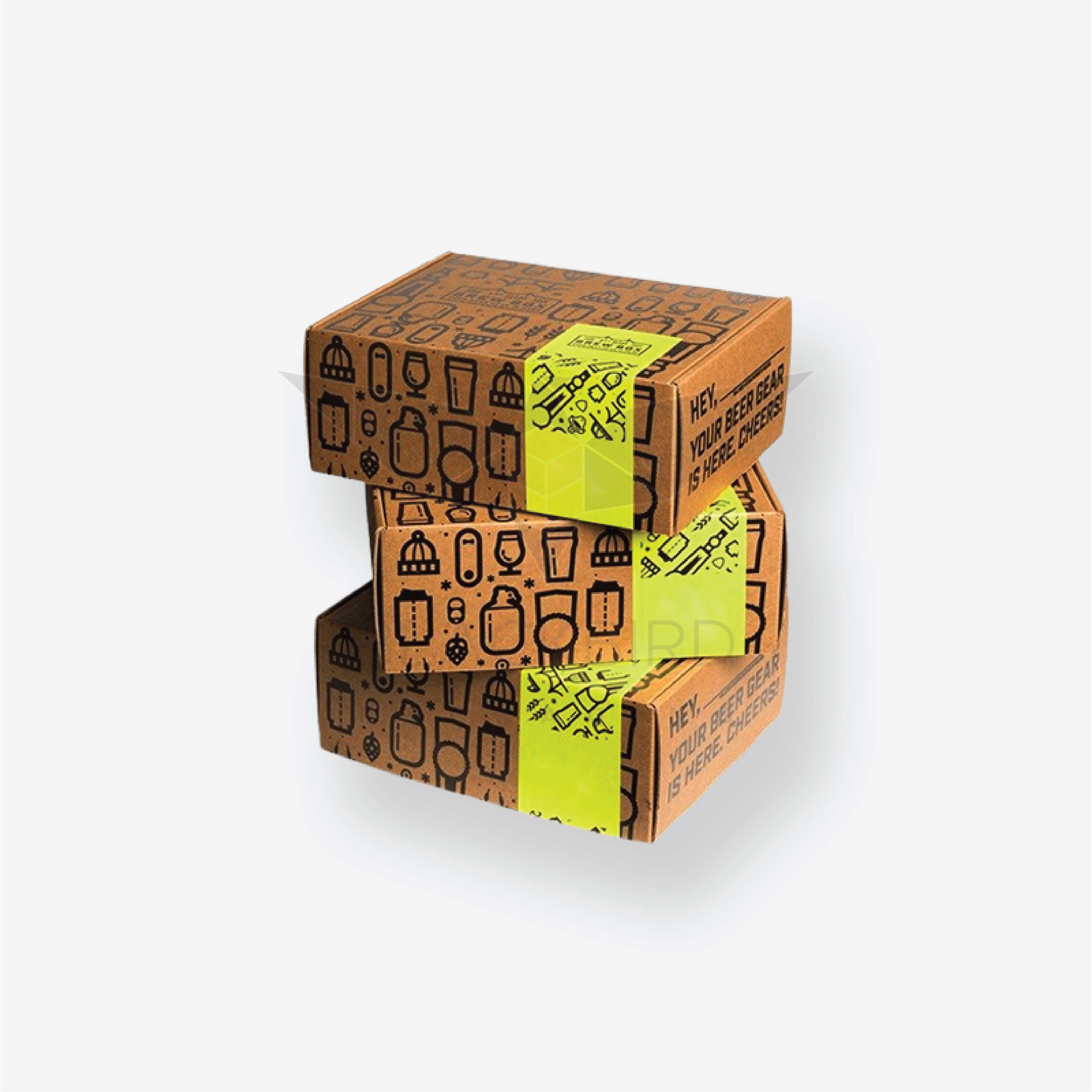

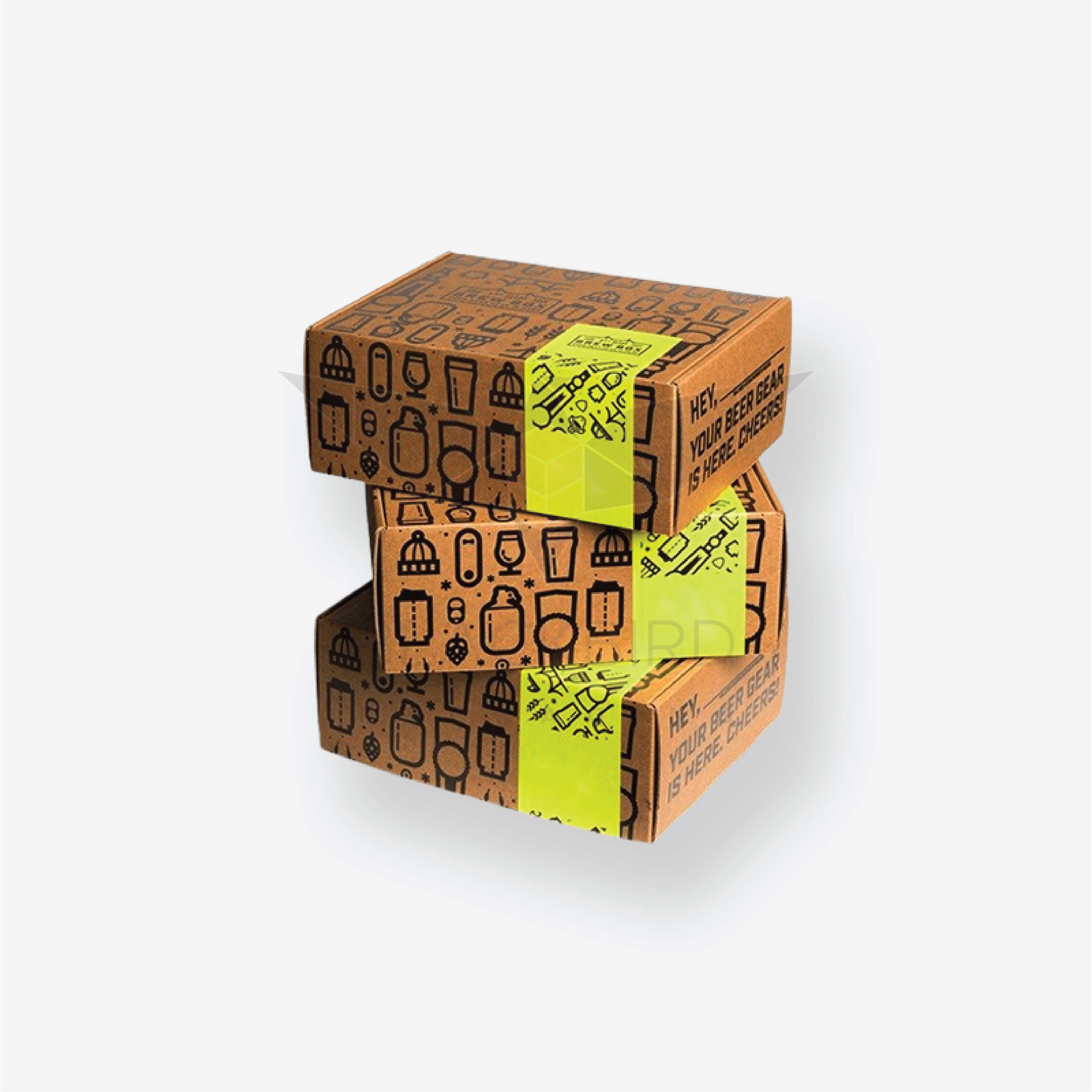

| Box Style | Customized, Tuck Flap Box, Pillow Box, Gable Style , Sleeve Style Box , Mailer Style Collapsible Mag Closure etc. |

| Dimension | Dimension or the size of the box is usually measured with the help of Length x Width X Height Formula ( Height = Top to Bottom of the box), Width (Left to right of the box) and Length front to back of the box. |

| Size | All Custom Size and standard sizes are Available. |

| Quantities | 100 to 500,000 boxes can be ordered in one month. |

| Paper Stock | 10pt to 24pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock, Uncoated Super White Cardboard and Rigid Stock. |

| Printing Type | Offset printing Method, Screen Printing, Plain, CMYK Colors, PMS (Pantone Matching System), Spot Colors. |

| Finishing Or Add ons | Soft Touch Lamination ,Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing Debossing and Foiling. |

| Additional Options | Creasing , Die Cutting, Gluing, Perforation, Blind Embossing, Window Patching, (Gold, silver, Copper, Red, Blue Foil Stamping) |

| Design Proofing | Box Template (free), Flat View, 3D Mock-up, Physical Sampling (On request Paid) |

| Turnaround Time | Standard Turnaround Time:After getting the artwork approved, it takes 9 to 11 business days for producing the boxes and further 24 to 48 Hours for the shipment to be delivered at your doorstep. Custom add on orders can take 2 to 4 days extra. |

| Expedite Turnaround Time | Once the job is sent for production after the approval of artwork the production will take at least 4 to 6 Biz days for printing and further 24 to 48 hours for delivery at your doorstep. Urgent deadlines can be achieved. |

| Shipping services | We use DHL, FedEx USPS and UPS to Ship boxes. Sea shipping is also an option that can be considered on specific requests. |

You might Be Interested In These Similar Boxes

You may obtain a customized price quotation by:

A pricing quotation is normally sent within 2-4 working hours for most enquiries. Complex projects may need a quotation time of 24 to 48 hours. Throughout the quoting process, your account manager will keep you informed.

The following phases comprise the process of receiving your custom print orders:

A professional account manager will assist you with the different procedures. Our sales support staff is available to give extra information and answer any questions you may have.

We can make adjustments to your purchase before the manufacturing process begins. The project may need to be re-estimated depending on the nature of your proposed adjustments, in which case you will get an updated quotation.

Please bear in mind that custom printed things are one-of-a-kind and cannot be reused. In some circumstances, it may be possible to cancel an order throughout the various stages of production, however, cancellation costs will apply based on the quantity and nature of the work that has already been completed. Our customer service agents will educate you of any cancellation expenses. Once an order has completed the fabricating preparation and entered the shipment stage, it cannot be cancelled.

Yes, upon request, custom printed samples are available. For a little sampling charge, you may get hard copy copies of your own project. Alternatively, you may request a free sample of one of our previous printed products.

Orders are normally delivered 3-4 business days after they are ordered. Your account manager will keep you updated on the status of your project throughout the manufacturing and delivery stages.

Yes, we can send it anywhere in the world. Specific requests should be communicated to your account manager. Please keep in mind that foreign orders may incur extra shipping costs, customs fees, and taxes.